Solidworks Hide Body in One Drawing View

Ii years ago, in an article covering the SOLIDWORKS World 2019 Tiptop 10 Ideas Competition, I wrote:

There is ane thing CAD power-users have in mutual: They do not accept limitations in software functionality. Effort to say to power-users: "Y'all cannot do this," and they volition await at you similar you are an alien.

As a preparation and process consultant, working with hundreds of engineers and designers every yr, I learned 1 more affair SOLIDWORKS power-users have in common: they are so decorated designing the astonishing products that are improving our life, that they cannot spare a moment to improve their own.

Every bit we focus on tailoring new methods for improving power-users' productivity, each preparation session generates intense brainstorming events—harnessing the ingenuity and inventiveness of everyone involved. Not only practice we blueprint, effort, validate and finetune new techniques to solve their challenges, but we also push button the functionality of SOLIDWORKS to its limits. When that happens, in that location is e'er a user who comes up with a great idea for how the software should work improve. I am sure SOLIDWORKS Product Definition Managers would love to be a fly on the wall in these moments.

Even though they have great ideas for enhancing SOLIDWORKS' functionality, notwithstanding, few users tin can find the time to submit these ideas to the CAD vendor by post-obit the proper channels, every bit described in this commodity.

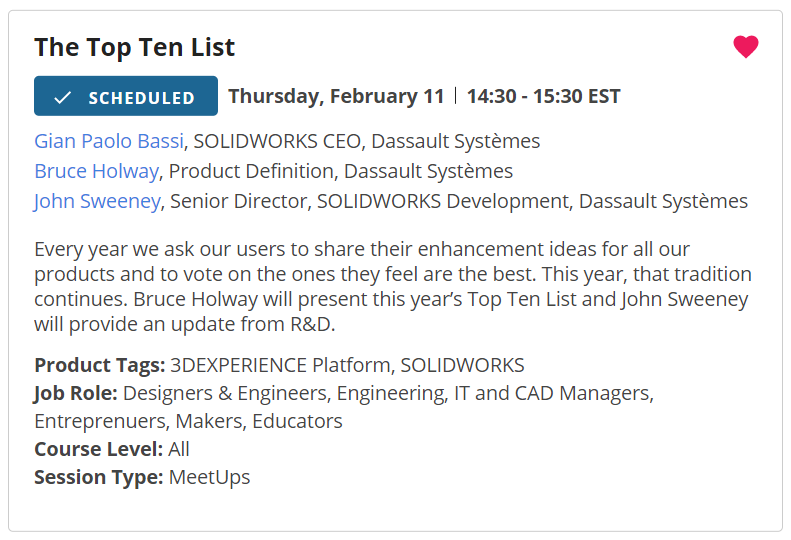

I hate to run into great ideas go to waste matter, so I decided to collect as many as possible from my customers and submit them to the SOLIDWORKS Peak Ten 3DEXPERIENCE Earth 2021. Since we already established that your time is precious, I will not get in details explaining how the Top Ten List 2021 (also knows as TTL21) is the surest way to maximize the chance that your enhancement requests volition be implemented in the next releases of SOLIDWORKS. If y'all accept time and are curious, delight read these 2 articles to empathize how the Top 10 Event came to be and everything about how the event was implemented this year.

Instead, I volition attempt to salve you the fourth dimension past proposing a curated list of ten ideas for your voting considerations. The criteria for selecting these ideas are:

- Maximize the positive impact in productivity.

- Easy to implement from the developer's perspective.

- Focused on large assembly and drawing workflows.

[Update 02/03/21: The voting is complete, now is the time to see the results. Don't miss the Height X List MeetUp at 3DEXPERIENCE Globe 2021 with Gian Paolo Bassi, the CEO of SOLIDWORKS and the SOLIDWORKS R&D and Product Development Teams.]

Pace 1: Register on the 3DEXPERIENCE Platform

This twelvemonth, the SOLIDWORKS Elevation Ten List is hosted on the 3DEXPERIENCE Platform. If you lot do not take yet a user ID, you tin can register for free using this link.

One time your account is created, please login into the 3DEXPERIENCE Platform and follow the links below.

Without further ado, this is the list nosotros curated for yous:

- ESCAPE Key should always stop the current process and revert to the state earlier it

- Ability to Open a Subassembly in Large Pattern Review manner

- Drawing Detailing Mode from Associates Large Design Review Mode

- Add together Marker-ups to the Big Design Review Mode

- Power to come across Snapshots and Marker-ups when a SOLIDWORKS file is opened in eDrawings

- Manage Display States with Tables

- BOM to Filter Visible Components

- Make "Include Detailing Mode Data when saving" a Document Setting instead of a System Setting

- Enhance the 3DInterconnect Robustness

- Make Holding Tabs – File Type Agnostic

How to Vote on an Idea

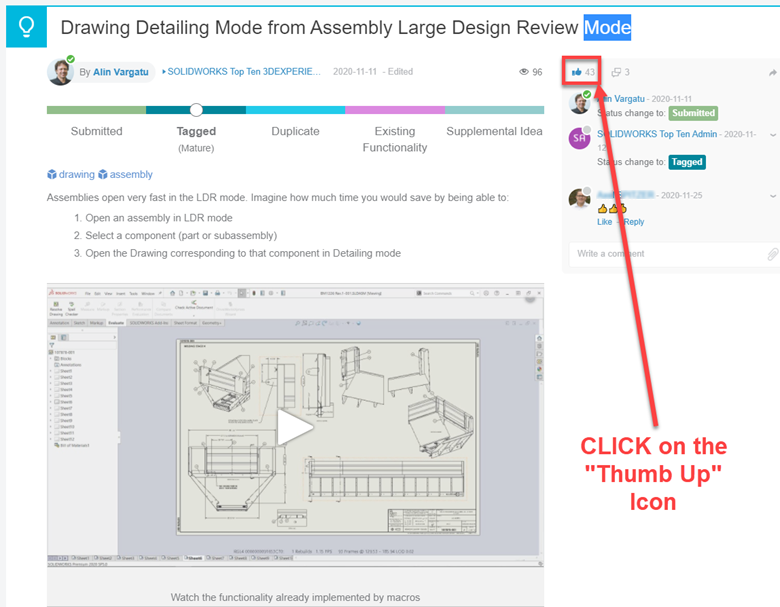

The voting process is very simple, just "similar the idea" to record your vote (Effigy 1).

Effigy 1: Give a "Thumbs Up" to the ideas yous would similar to see implemented in the next releases of SOLIDWORKS.

For more in-depth data almost the voting process, read this article.

Now, let'due south explore these ideas in order to gauge their potential for improving your productivity.

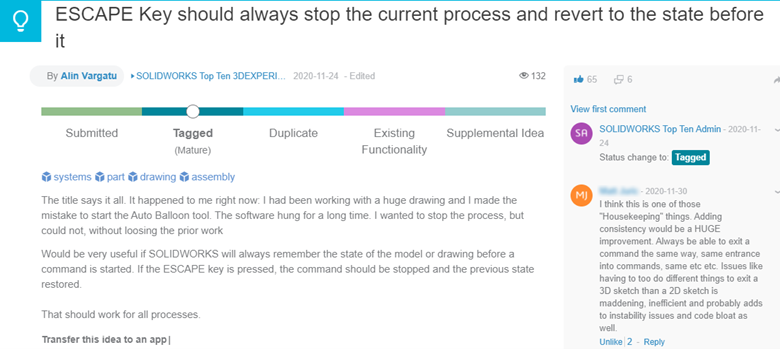

#1 Escape Key Should Always Terminate the Electric current Process and Revert to the State Before It

Clarification of the problem:

In SOLIDWORKS, the Escape key has many roles, depending on when it is being used. Its main function is to abolish an existing dialog box and return the user to the previous activity. For example, the user could shut the PropertyManager dialog of a characteristic and return to the part environment without changing the settings of that feature.

For a reduced set of commands, the Escape key could terminate a process without loss of information. Unfortunately, that works in a small number of cases and is non always consistent.

For example, Escape volition not interrupt a long computation procedure such equally displaying a preview paradigm of a feature. When the user knows that the preview volition take tens of minutes, the only pick to stop it is to crash the SOLIDWORKS session. That is not e'er possible due to loss of data since the last save. Every bit a issue, the user has a painful choice to make:

- Waste tens of minutes—or fifty-fifty hours—waiting for the preview to exist computed and displayed.

- Crash SOLIDWORKS and potentially lose hours of work since the final save.

Effigy 2.

Benefits subsequently implementation:

- Save a significant amount of time. For some users, this could be measured in hours per week.

- Improve consistency in the user experience (UX). The Escape key in SOLIDWORKS would have like behaviour to what it has in about Windows programs.

How to implement it:

Ideally, the software will always enshroud the current state in RAM before any new activity is initiated by the user. When the Escape key is pressed, the current procedure will stop and SOLIDWORKS volition instantly return the model to the cached state.

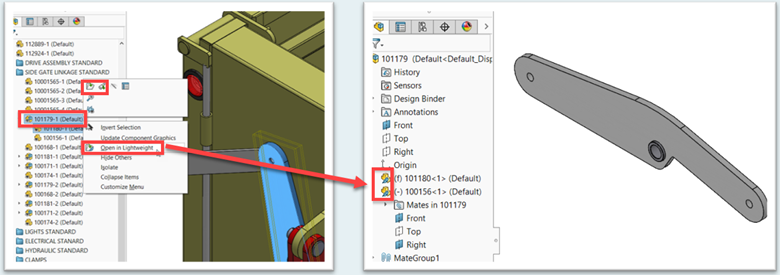

#2 Ability to Open a Subassembly in Large Design Review mode

Description of the problem:

In SOLIDWORKS, the Big Design Review mode (LDR) is the best mode to open humongous assemblies in seconds past loading simply the graphics information saved in the assembly file. The experience is like opening the assembly in eDrawings.

In the last 3 releases of SOLIDWORKS, this functionality has been enhanced tremendously. Users can perform many activities in this way:

- Utilize the model equally a Visual Directory to find and open components.

- Hibernate, bear witness or isolate components.

- Generate graphics-but planar section views.

- Measure.

- Apply a "Camera" to navigate through the assembly without hiding or sectioning.

- Access the Operation Evaluation tool.

- Set up and use Snapshots to preserve the orientation, the Hide and Show country of components, and the Section View state.

- Review dissimilar assembly configurations.

- Selective Open the assembly for quick revisions or design validation studies

- Edit Associates in Large Design Review Manner to delete components, add together components, edit component positions, add/delete/edit mates, and add linear and round patterns.

I of the most mutual activities is the first one on the list: finding and opening components from the graphics area or from the FeatureManager tree.

Currently, from an associates opened in LDR mode, y'all tin open a subassembly in both resolved and lightweight modes, only non in LDR mode.

Figure 3. Current opening modes.

This limitation prevents users from performing very fast editing workflows, such equally the one described below:

- From the top-level associates opened in LDR mode, select one or more subassemblies.

- Press a button to open the selected subassemblies in LDR mode.

- Edit a subassembly open in LDR mode.

- Add and mate a new component.

- Salvage the subassembly and update the LDR graphics data.

- Return to the main assembly.

- Edit the main assembly.

- Salvage all files.

Benefits later implementation:

- This will enable users to relieve a huge amount of time when working with very large assemblies. In our tests, we were able to insert a large component into a large subassembly, mate it in position, so return to and update the height-level associates in under five minutes, compared with 27 minutes using conventional techniques.

How to implement it:

To illustrate the results of this enhancement, we partnered with Artem Taturevych from XARIAL to implement this functionality using API. Delight watch this video for a proof of concept for ideas #2 and #iii:

Video 1. Open up Subassembly in LDR mode from LDR and Open up Cartoon in Detailing fashion from LDR.

#three Drawing Detailing Mode from Assembly Large Blueprint Review Style

Clarification of the problem:

The introduction of the Detailing style was a game changer for users of large drawings. If you are curious, you could read how this revolutionary enhancement was implemented in SOLIDWORKS in this commodity.

By not having the model loaded in the RAM, drawings open instantaneously in this manner. Operational speed is also maximized for:

Calculation secondary views:

- Detail views

- Cleaved views

- Crop views

- Empty views

Reposition:

- Views

- Dimensions

- Annotations

- Tables

Add and edit:

- Dimensions

- Annotations

- Revision Tables

- General Tables

Print and Salvage to PDF, DXF, DWG and more than

What is not currently possible is to open up a drawing from an associates opened in LDR mode.

Benefits after implementation:

Users will save a huge amount of time, every bit shown in Video 1. Moreover, the user tin can select multiple subassemblies from the top-level assembly opened in LDR mode and their drawings can be opened in seconds in Detailing mode.

Typical workflow:

- Open up Top-level assembly in LDR.

- Select one or more than subassemblies.

- Press a button to open their drawings in Detailing mode.

- Perform cartoon activities every bit described to a higher place.

- Save the drawing(south).

- Return to the assembly opened in LDR.

How to implement it:

For a proof of concept, delight lookout man Video i shown above.

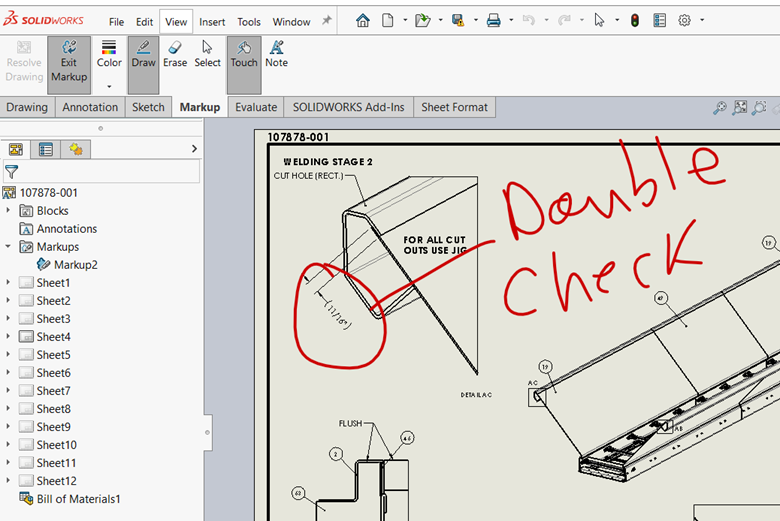

#four Add Mark-ups to the Big Design Review Mode

Description of the problem:

At many companies I piece of work with, the checkers take tons of newspaper in front end of them and a carmine pen. They manually redline everything and and so send the sheets dorsum to the SOLIDWORKS users. There is not an inch of space on anyone'southward desk-bound not covered in paper.

Once these checkers encounter the new markup functionality for assemblies (SW2019) and drawings (SW2020), they get extremely excited. The checkers do not fifty-fifty demand to acquire how to utilize SOLIDWORKS, they only demand to learn how to use markups. Information technology's a expert opportunity to ask for and become a tablet or a touchscreen for paw-written markups.

Moreover, markups can now be added and edited in the Detailing fashion for drawings, making them even more useful for users.

Effigy 4. Markup created in Detailing mode.

Unfortunately, markups are non accessible in the Large Blueprint Review fashion for assemblies. Not only can markups not exist created in LDR mode, but they are also non even visible.

Benefits after implementation:

Giving all users (checkers, managersand power-users) access to markups in Big Design Review mode would completely alter the workflows for sharing information:

- During the checking process.

- Sharing information with members of the team.

- Sharing data with 3rd parties, including customers or suppliers.

- Quickly documenting of import information during design review meetings directly in the assembly file.

How to implement information technology:

SOLIDWORKS already proved that comments added to snapshots can exist accessible in LDR mode. In improver, annotations can be added in eDrawings style. Expanding this functionality for markups in LDR mode might not exist an easy project, but the return on investment is huge.

#5 Ability to Run into Snapshots and Marker-Ups When a SOLIDWORKS File is Opened in eDrawings

Description of the problem:

Snapshots are fantastic for users who work with Large Assemblies, and they work particularly well in the Large Design Review mode. With Snapshots, with one click users can access:

- Hibernate/show state of components.

- Section view country.

- Orientation.

- Comments.

As described in a higher place, there aren't plenty not bad things to say well-nigh markups. They save trees and hours of work for checkers, managers, users, manufacturing personnel and anyone else who requires data.

More importantly, you do not demand to be a SOLIDWORKS power-user to use snapshots to navigate through the model and substitution data with markups. Anyone can be trained in minutes on how to open an associates in LDR mode and take reward of these tools.

Unfortunately, most employees from other departments practice non have admission to SOLIDWORKS. They will open up models using the eDrawings software, which currently does not include functionality for accessing SOLIDWORKS snapshots and markups.

Benefits afterward implementation:

Giving all stakeholders admission to snapshots and markups from eDrawings volition exist a game changer for the whole company. The need for newspaper-based communication will decrease significantly. Moreover, the SOLIDWORKS users will no longer be interrupted from their work by colleagues from other departments with questions that can take instant answers in existing snapshots and markups.

How to implement information technology:

eDrawings already allow access to complex information from the SOLIDWORKS part, assembly and drawing files. Unlocking the access to Snapshots should exist like to the current access to 3DViews.

Allowing admission to Markups will probably be more than difficult, since markups are in essence 2D sketches.

#half dozen Manage Display States with Tables

Description of the problem:

Imagine receiving a circuitous client assembly model made of several components. Your role is to pattern the whole process for welding all the components together. That would involve the blueprint of several cells, including robots, conveyors and all kind of other fixtures and machines.

For that, you would need to create a model of the customer function for each phase of the manufacturing process. As an example:

Phase 1: Show only parts A and B and their weld points (weld points are commonly represented as spheres).

Stage ii: Evidence Parts A, B and C, and the weld points relevant for this phase.

…

Phase n: Show Parts A, B, C, D… north, and the weld points relevant for this phase.

…

To configure and manage such a complex variation, near users use configurations and design tables. This is all well and good until the higher-level assemblies need to use tens of copies of the same client model with various configurations.

In that case, for each instance of the model in a unique configuration, SOLIDWORKS needs to load a dedicated set of torso data. So, if the associates requires 30 different configurations of the same model, information technology will load 30 different body sets. The functioning degrades exponentially with the increased number of configurations.

This upshot was more than significant in earlier versions of SOLIDWORKS (before 2020). The software was unable to read torso data stored in inactive configurations.

The solution? Use Brandish States instead of configurations. You could store each phase in a separate display land and simply hide all components not needed past each display state. Since multiple brandish states can share the aforementioned internal model, the problem is solved. If the higher assembly loads 30 different display states of the aforementioned model, in the same configuration, only one body data set would exist loaded. The deviation is huge.

Unfortunately, managing displays states is currently a transmission process. This makes their use very cumbersome and might even forestall users for adopting them.

The solution is simple: allow display states managing with tables, like to configuration management.

Benefits afterwards implementation:

Once the display states table management is implemented, users will be able to take total reward of the lighter data from brandish states. File sizes, open times and cartoon view update time will decrease drastically (by a factor of 2 to 10 or more).

How to implement it:

Simply use the aforementioned tools that work well for configurations:

- A tool similar to Configure component tables.

- Design tables.

#7 BOM to Filter Visible Components

Description of the problem:

Imagine how much easier yous could document cartoon views if you could inquire the BOM to hide all hidden components, and also give you lot the option to maintain the particular numbers unchanged (simply hiding the rows of hidden components) or renumber the items.

This manner, individual BOMs attached to specific drawing views would make an Assembly Procedure describing drawing a breeze.

Currently, users are forced to create separate configurations for each BOM (with all the consequences described in idea #6) or painstakingly hide BOM rows, which destroys the parametric epitome backside the BOM.

This idea would work well with idea #6 – Display States Managed past Tables.

Benefits afterwards implementation:

Implementing this simple idea will drastically reduce the complexity of models and drawings used for describing a process, every bit well every bit reducing the number of files and configurations required for that.

How to implement it:

Add together a checkbox in the PropertyManager of a BOM table: Ignore hidden components.

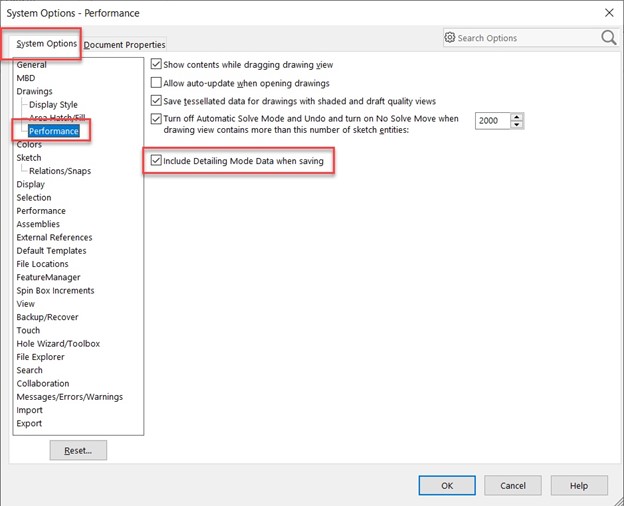

#eight Make "Include Detailing Fashion Information When Saving" a Document Setting Instead of a System Setting

Description of the trouble:

Every bit described in thought #3, the Detailing way for drawings is a game changer. It works past saving more information in the drawing file, by and large related to existing edges and their IDs. That, unfortunately, creates two less desirable consequences:

- Larger file sizes (all that independent info needs to be stored somewhere).

- Long saving times for drawings that have shaded views or draft quality views.

Considering that 95 per centum of SOLIDWORKS drawings are simple enough not to need the use of the Detailing style, information technology is important to give the users the power to make up one's mind how much information to save in the file.

Currently SOLIDWORKS 2020 and 2021 have implemented this user control as a Organisation Option:

Figure 5. Relieve Detailing Mode Data.

This is less than ideal for 2 reasons:

1. It does not allow users to customize the amount of data saved per file. Ideally:

- Simple drawings should have this pick unchecked.

- Circuitous drawings should have the option checked.

2. It potentially creates major bug for teams of users. One user, who has this organization option unchecked, could open a large cartoon, save information technology and erase the detailing data. Then, when a power-user needs to open the drawing in Detailing way, it would be impossible.

Later on all, ensuring team-level consistency is disquisitional.

Benefits later on implementation:

Reduce saving times, increase consistency in the team and simplify file management.

How to implement it:

This pick should be a document level setting, allowing the user to determine whether to relieve the drawing with the Detailing data included or non.

To simplify the workflow, the Save dialog can as well have a checkbox chosen Detailing Data to allow the user to brand such decisions.

Information technology might fifty-fifty exist worth considering having a Large Drawing Mode, similar to the Big Assembly Mode, where the software can determine to save or not save Detailing information based on the rules related to the number of drawing views set to Shaded or Shaded with Edges, or related to other factors known to ho-hum down the detailing process.

#9 Raise 3DInterconnect Robustness

Description of the problem:

Nosotros described the benefits of the new 3DInterconnect import engine in The Ultimate Guide to Working with Pace Files series of manufactures.

The limitations of this tool take been very well documented in the SOLIDWORKS Knowledgebase. Fixing these three SPRs would remove most of the issues reported by users:

- Electric current regression: SPR 1180136: Non-native file inserted in assembly as 3D Interconnect characteristic does not show refresh icon (symbol) in FeatureManager Tree when its geometry is changed.

- Current limitation: SPR 1072694: 3D Interconnect – Ability to maintain the downstream features (mates) in a SW file when the linked STEP file'due south geometry is updated.

- Current regression: SPR 1187494: STEP – Consign and Import – weldment office – changing the dimension of the structural member, the gild of body will change once re-imported.

Benefits later on implementation:

Huge fourth dimension savings during revisions, reducing errors and improving productivity.

How to implement it:

Simply accost the documented bug.

#10 Brand Property Tabs File Type Agnostic

Currently, there are four unlike types of property tabs for:

- Office

- Assembly

- Weldment

- Drawings

In that location should exist only one property tab, which would work for all document types. This will exist easy to manage and much easier to use.

For example, in a pinnacle-level assembly, a Select all components command would exist followed past applying a property value to all of them, regardless of whether they are sub-assemblies or parts.

ii. If different components are already assigned different tabs, they cannot be selected together and processed by the property tab. This is a showstopper.

The ideal behavior is pre-selecting components, picking a sure tab template and applying it to all equally needed. For example, if yous accept a belongings tab that controls simply three properties, you lot should be able to select all components of the associates, pick that tab and change all those backdrop in bulk in twenty seconds. This is currently incommunicable.

Some of these bug were documented in:

SPR 458546: "Selected documents refer to unlike templates. When selecting multiple documents, each one needs to refer to the aforementioned template file" when selecting multiple component combinations that were non originally chosen to employ the custom backdrop.

SPR 836530: Provide ability to change a belongings of multiple components at once, fifty-fifty if they apply different custom belongings templates, just share a common property.

three. If SW would add a Cut List filter in the F5 filter box, it would unlock the functionality for Weldment Property Tabs. Imagine how easy would exist to add together, modify and manage cut list backdrop, straight from the graphics area. For instance:

- Turn the cut-list filter on.

- Click on several faces belonging to various bodies.

- Get the Holding Tab to testify the cut list properties associated to the items that take faces selected.

- Edit the properties at will.

Benefits after implementation:

User productivity would increment past 30 to 50 pct when working with metadata in weldments and sheet-metal parts.

How to implement it:

Unify the Property Tab functionality.

Summary

This is a once-in-a-yr opportunity for all of u.s.a. to vote on the most significant ideas for improving the SOLIDWORKS software. This article offered a curated list of ideas, focused by and large on increasing productivity for large assembly and drawing users.

If you have time, do not stop here. Read the residual of the ideas and vote on all the ones yous believe would meliorate your productivity and your quality of life. So curate your own lists and send them to your friends and colleagues to vote for.

There is ability in numbers!

Join in to come across the results during the Top 10 List MeetUp at 3DEXPERIENCE Earth 2021!

To learn more most SOLIDWORKS, check out the whitepaper Developing Meliorate Products in the Cloud.

mcneilhartatied1956.blogspot.com

Source: https://www.engineersrule.com/10-life-changing-enhancement-ideas-for-solidworks-users/

0 Response to "Solidworks Hide Body in One Drawing View"

Post a Comment